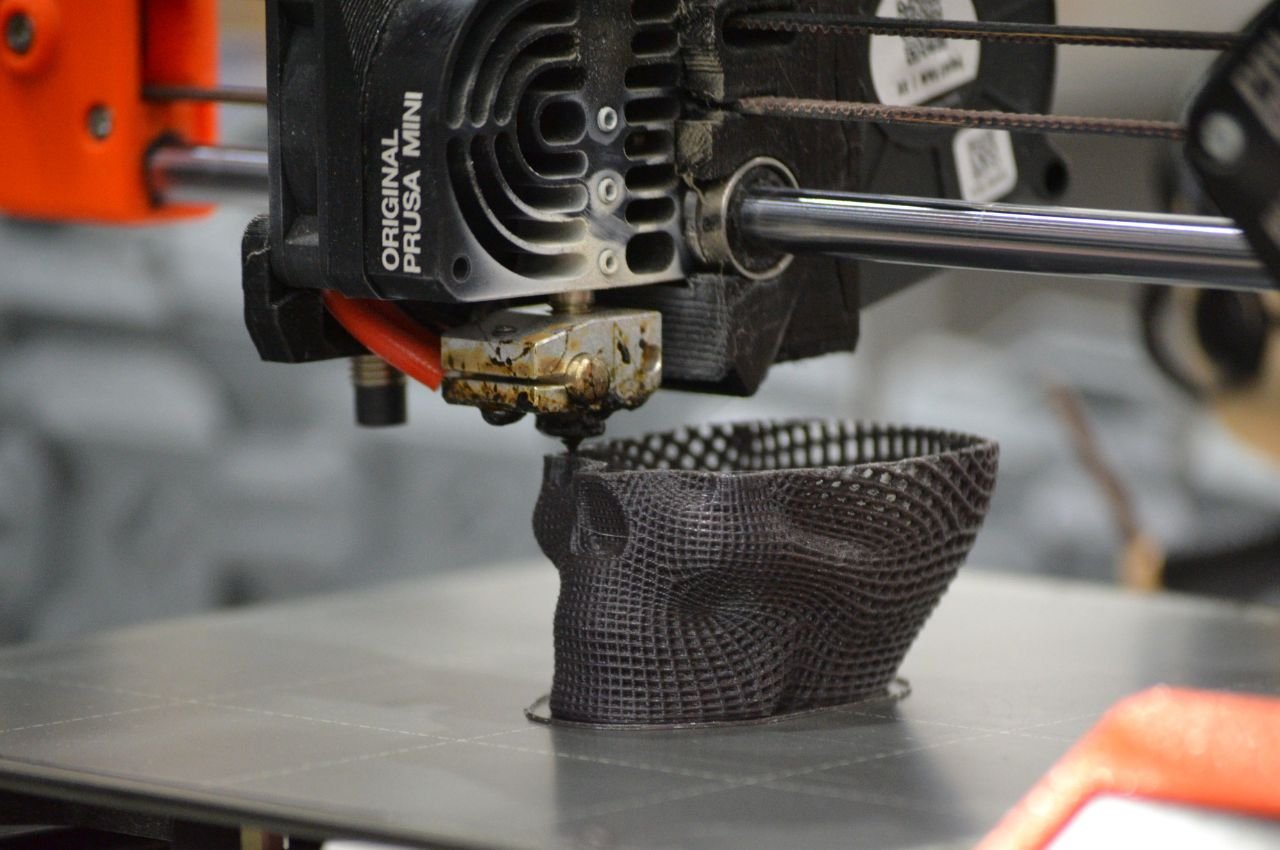

Explore Leading 3D Fabrication Services with Ripley Dynamics

At Ripley Dynamics, we redefine precision and efficiency with our top-tier **3D fabrication service**. Located strategically in Australia, we cater to a wide range of industries including aerospace, automotive, and healthcare. Our state-of-the-art technology and skilled team ensure that every project, from simple components to complex assemblies, is executed with unmatched accuracy. We specialize in **metal 3D printing**, a cornerstone technique that pushes the boundaries of traditional manufacturing to offer you quicker turnaround times and enhanced product quality.

Advanced Metal Additive Manufacturing Solutions

Dive into the future with Ripley Dynamics’ **metal additive manufacturing** services. This process, which includes sophisticated methods like **Direct Metal Laser Sintering (DMLS)** and **Selective Laser Melting (SLM)**, allows for the creation of **custom metal parts** with high precision. Our services are designed to meet the specific needs of your projects, providing the flexibility to produce parts with complex geometries that are otherwise challenging to fabricate through conventional methods. This adaptability makes our services ideal for industries requiring bespoke solutions and intricate designs.

Custom Metal Parts and Prototyping

Innovation is at the heart of Ripley Dynamics as we offer tailored **custom metal parts** production. Whether you are looking for one-off prototypes or full-scale production runs, our **metal prototyping** and **rapid prototyping** services stand out in the industry. Utilizing advanced techniques such as **Electron Beam Melting (EBM)**, we ensure that every part meets the stringent standards for strength, durability, and detail. Our rapid prototyping capabilities allow you to iterate and refine your designs quickly, reducing the time from concept to market.

Excellence in Metal Prototyping

At Ripley Dynamics, our **metal prototyping** expertise is unparalleled. With a focus on **Direct Metal Laser Sintering (DMLS)**, we cater to sectors that demand high performance and precision. This technique is perfect for applications in environments that challenge the durability and integrity of parts. By offering solutions that transition smoothly from prototyping to production, we ensure that you can test and validate your designs effectively, leading to better end products and streamlined development processes.

Swift Metal Services by Ripley Dynamics

Under the umbrella of **Swift Metal Services**, Ripley Dynamics continues to lead in the provision of comprehensive **3D printing services**. Our commitment extends beyond traditional fabrication methods to embrace innovative technologies that offer scalability and flexibility. Whether you need a prototype or mass production, our solutions are tailored to your exact specifications, ensuring that every project achieves its potential in both design and functionality. Trust us to bring your ideas to life with precision and speed, reinforcing your market position with superior product offerings.

High-Quality Metal 3D Printing at Ripley Dynamics

When precision meets perfection, you get Ripley Dynamics' **high-quality metal 3D printing** services. We specialize in producing **3D printed metal parts** that are not just components but critical enablers of innovation and efficiency across industries. Our advanced **metal 3D printing services** harness technologies like **Selective Laser Melting (SLM)** and **Electron Beam Melting (EBM)**, ensuring that every layer of printed metal meets rigorous standards of strength and precision. This high level of detail supports industries where part performance can be a life-or-death matter, such as in medical implants or aerospace components. By focusing on quality at every step of the fabrication process, from digital design to the final post-processing, we provide products that significantly outperform traditional metal fabrication in both complexity and performance.

Affordable Metal 3D Printing Solutions by Ripley Dynamics

Cost-efficiency in manufacturing is crucial for businesses to maintain competitive edges, and Ripley Dynamics’ **affordable metal 3D printing** services ensure this without compromising on quality. Our streamlined production processes minimize waste and increase efficiency, allowing us to pass on the savings to our clients. This affordability makes our **metal 3D printing services** accessible to a wider range of businesses, from startups needing prototypes to established companies looking to innovate their production lines. With Ripley Dynamics, affordability means that you can experiment with complex designs and new materials without the high costs traditionally associated with metal fabrication. Embrace the future of manufacturing that supports both your budget and your ambitions to innovate and grow.

Streamlined Production of 3D Printed Metal Parts

At Ripley Dynamics, the production of **3D printed metal parts** is refined to an art form. Utilizing state-of-the-art **metal 3D printing services**, we offer tailored solutions that fit the specific needs of your projects. Whether it's a part for a crucial aerospace component or a bespoke piece for automotive innovation, our technology provides the capability to produce with precision and efficiency. Our commitment to using only the best materials and advanced printing technologies like **Direct Metal Laser Sintering (DMLS)** and **Selective Laser Melting (SLM)** ensures that each part is built to last, with properties that often exceed those of their traditionally manufactured counterparts. With Ripley Dynamics, expect a seamless process from design to delivery that guarantees the integrity and functionality of every printed metal part.