3D Laser Cutting Services: Precision and Innovation in Australia

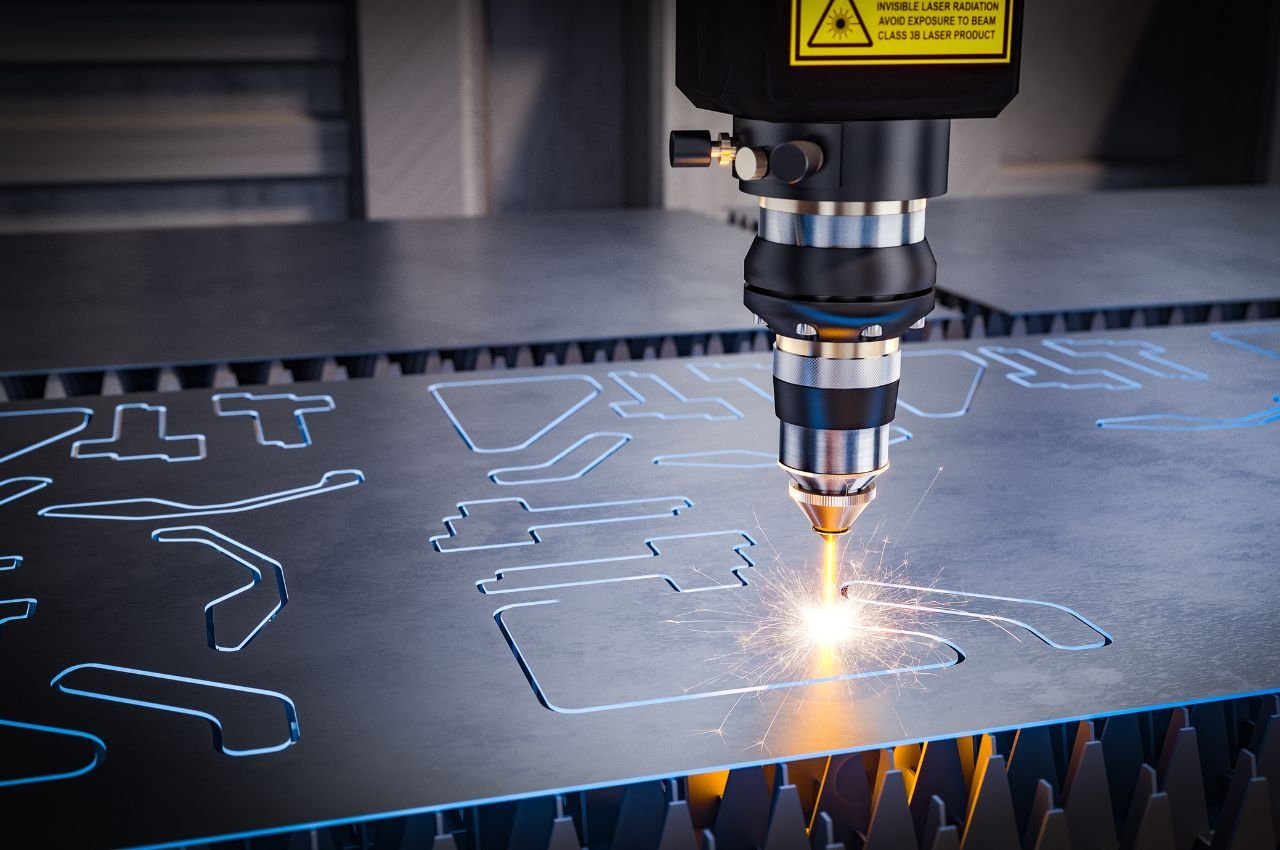

At Ripley Dynamics, our 3D laser cutting services represent a fusion of precision and innovation, setting a new standard in Australian manufacturing. Utilizing state-of-the-art laser technology, we provide cutting solutions that offer unmatched accuracy and intricacy. Our 3D laser cutting is capable of handling complex geometries and delicate cuts on a variety of materials, including metals, plastics, and composites.

This technology is ideal for projects requiring intricate designs and high precision, such as aerospace components, intricate automotive parts, and detailed architectural models. Our 3D laser cutting service is not just about precision; it's also about flexibility. We can accommodate a wide range of sizes and material thicknesses, ensuring that our clients’ specific needs are met with the highest quality and efficiency.

Our commitment at Ripley Dynamics is to deliver excellence in every cut. We ensure that every project, no matter how complex, is executed with the utmost precision and care, leveraging our 3D laser cutting services to bring our clients' visions to life with unparalleled accuracy and speed.

The Power of Metal Laser Cutting: Advanced Techniques for Superior Results

Metal laser cutting at Ripley Dynamics is where advanced techniques meet superior results. Our laser cutting services are designed to deliver precision cuts on various metals, including steel, aluminum, and brass, with a high degree of accuracy and efficiency. Using the latest laser technology, we can produce clean, burr-free cuts with complex contours and intricate details that traditional cutting methods cannot achieve.

This advanced capability is particularly beneficial for industries requiring precise metal components, such as the automotive, aerospace, and engineering sectors. Our metal laser cutting is not only precise but also fast, enabling rapid production and short turnaround times. This efficiency is crucial in today’s fast-paced market where speed without sacrificing quality is paramount.

At Ripley Dynamics, we understand the nuances of working with different metals and adjust our cutting techniques to suit each material’s properties. This ensures optimal cutting results, with minimal material wastage and maximum structural integrity of the cut parts, supporting our clients in achieving excellence in their projects.

CNC Laser Cutter Capabilities: Versatility in Cutting and Engraving

Ripley Dynamics' CNC laser cutter capabilities embody versatility, offering both cutting and engraving solutions for a wide range of applications. Our CNC laser cutters are equipped with advanced technology that allows for precise cutting of various materials, including metals, plastics, and woods, with intricate detail and excellent edge quality. These capabilities extend beyond cutting to intricate engraving, enabling us to add detailed graphics, text, and designs to a variety of surfaces.

This dual capability of cutting and engraving makes our CNC laser cutters highly versatile tools for a range of applications. From creating detailed prototypes and custom parts to adding branding or decorative finishes to products, our laser cutters are capable of transforming materials into high-quality, custom creations.

Our team at Ripley Dynamics is skilled in optimizing the capabilities of our CNC laser cutters to meet the unique needs of each project. Whether it’s producing finely cut components or engraving intricate designs, we deliver precision and quality that enhances the value and appeal of the final product.

Expertise in Tube Laser Cutting: Shaping the Future of Metal Fabrication

At Ripley Dynamics, our expertise in tube laser cutting is shaping the future of metal fabrication. This specialized area of laser cutting allows us to precisely cut and engrave tubes and pipes, making it ideal for industries like construction, automotive, and industrial manufacturing. Our tube laser cutting technology can handle a range of materials, including steel, stainless steel, and aluminum, with high precision and efficiency.

The advantage of tube laser cutting lies in its ability to produce complex geometries, including angled cuts, contours, and holes, with a high degree of accuracy. This capability is essential for creating custom parts and components that fit together seamlessly, reducing the need for additional processing and assembly.

Our team’s expertise in tube laser cutting means we can take on challenging projects and deliver results that meet strict specifications and quality standards. By leveraging this advanced technology, Ripley Dynamics is committed to providing innovative solutions in metal fabrication, enhancing the efficiency and capabilities of our clients’ projects.

The Art of Laser Engraving: Adding Detail and Precision to Your Projects

Laser engraving at Ripley Dynamics is an art form that adds detail and precision to various projects. Our laser engraving services provide a way to add intricate designs, text, and images to a wide range of materials, including metals, plastics, glass, and wood. This technology is perfect for custom branding, personalized products, or adding detailed instructions or identifiers to industrial parts.

The precision of our laser engraving allows for fine detail and consistency across every engraving, ensuring high-quality results every time. This technique is ideal for applications ranging from creating unique promotional items and awards to engraving barcodes and serial numbers on industrial components.

Our team at Ripley Dynamics combines technical expertise with creative skills to offer laser engraving services that meet the diverse needs of our clients. Whether you’re looking to add a personal touch to a product or enhance the functionality of a component, our laser engraving services deliver accuracy, precision, and quality.

Custom Sheet Metal Fabrication & Cutting: Tailored Solutions for Your Needs

Ripley Dynamics specializes in custom sheet metal fabrication and cutting, offering tailored solutions designed to meet the specific needs of our clients. Our services combine precision technology with skilled craftsmanship, enabling us to handle a wide range of projects from simple to complex designs. We work with a variety of metals, including aluminum, stainless steel, and copper, offering flexibility in both material choice and fabrication techniques.

Our custom sheet metal fabrication services include cutting, bending, welding, and assembling sheet metal into the desired shapes and sizes. We leverage state-of-the-art machinery, such as advanced laser cutters and CNC press brakes, to ensure high precision and consistency in every piece we fabricate. This allows us to produce components that fit perfectly into your larger assemblies or stand-alone products with high aesthetic and functional quality.

Whether you require prototypes, custom parts, or large-scale production runs, Ripley Dynamics is equipped to deliver. Our team collaborates closely with clients to understand their requirements and bring their ideas to life with the highest levels of accuracy and efficiency.

Exploring the Depths: Materials and Techniques in 3D / 5 Axis Laser Cutting

Ripley Dynamics delves deep into the potential of 3D and 5-axis laser cutting, exploring an array of materials and advanced techniques. Our capabilities extend beyond traditional 2D laser cutting, enabling us to handle complex three-dimensional shapes and intricate contours with exceptional precision. This advanced technology allows for cutting a variety of materials, including but not limited to, stainless steel, aluminum, titanium, and specialized alloys.

The 3D and 5-axis laser cutting process is defined by its versatility and precision, capable of producing complex geometries that would be challenging or impossible with conventional methods. This technique is ideal for applications requiring intricate cuts and bevels, such as custom automotive parts, aerospace components, and intricate architectural designs.

Our skilled team utilizes the latest advancements in laser technology, combined with a deep understanding of various materials and cutting techniques, to deliver high-quality results. This ensures that our clients receive parts that not only meet but exceed their expectations in terms of precision, quality, and functionality.

State-of-the-Art Equipment and Quality Management in 3D Laser Cutting

At Ripley Dynamics, we pride ourselves on using state-of-the-art equipment and strict quality management processes in our 3D laser cutting services. Our cutting-edge laser machines are capable of executing intricate designs with extreme precision, which is essential for creating high-quality components in industries such as aerospace, automotive, and medical devices.

Our quality management process is integral to our operations, ensuring that every piece we produce meets stringent standards. We conduct rigorous inspections at every stage of the production process, from the initial design review to the final quality check of the finished product. This meticulous approach guarantees that we consistently deliver products of the highest standard.

Investing in the latest technology and maintaining strict quality control are cornerstones of our commitment to excellence. Our clients can have full confidence in the reliability and precision of our 3D laser cutting services, knowing that their projects are in the hands of skilled professionals equipped with the best tools in the industry.

The Advantages of Choosing Professional 3D Laser Cutting Services

Choosing professional 3D laser cutting services, like those offered by Ripley Dynamics, comes with a multitude of advantages. The precision and versatility provided by 3D laser cutting technology make it a superior choice for complex and detailed designs. Unlike traditional cutting methods, 3D laser cutting allows for intricate cuts and engravings on a variety of materials with high precision, without the need for physical contact with the material, thus reducing the risk of material deformation or damage.

Furthermore, the efficiency of 3D laser cutting significantly reduces production time, enabling quicker turnaround times for projects. This efficiency, combined with the precision of the cuts, often results in lower overall production costs. Additionally, the flexibility of 3D laser cutting technology makes it ideal for both prototype development and full-scale production, adaptable to a wide range of industries and applications.

With Ripley Dynamics, clients can expect a seamless and customized service, benefiting from our expertise in handling diverse materials and complex projects, ensuring their visions are accurately brought to life with the highest quality.

Types of Sheet Metal Finishes: The Final Touch in Laser Cutting Services

The final touch in laser cutting services is the application of various types of sheet metal finishes, which not only enhance the appearance of the products but also provide additional protection. Ripley Dynamics offers a range of finishing options to meet the specific needs of different projects. These finishes include powder coating, which provides a durable and protective layer, available in a wide range of colors; anodizing, particularly for aluminum parts, offering corrosion resistance and aesthetic appeal; and painting, for a custom look that meets specific branding requirements.

Other finishes include brushing and polishing, which are ideal for creating a textured or reflective surface, and galvanizing, which offers added protection against corrosion for steel parts. Each finish type brings its own set of benefits and can be chosen based on the requirements of the application, such as environmental exposure, aesthetic considerations, or wear resistance.

Our team at Ripley Dynamics works closely with clients to recommend the most suitable finishes for their projects, ensuring that the final products not only look great but also have extended longevity and functionality.