Sheet Metal Fabrication at Ripley Dynamics

Sheet metal fabrication is a cornerstone of modern manufacturing, and at Ripley Dynamics, we excel in delivering top-notch services tailored to your specific needs. Located in the heart of Australia, we specialize in transforming raw metal into precise, functional products. Our capabilities span cutting, bending, welding, and forming—making us your go-to sheet metal fabricators. Whether you're looking for high-volume production or a unique custom project, our team is equipped with advanced technology and expertise to ensure precision and quality in every piece.

Custom Sheet Metal Fabrication Solutions

Understanding the unique demands of different industries, Ripley Dynamics offers custom sheet metal fabrication services designed to meet exact specifications. Our approach combines innovative technology with meticulous craftsmanship, allowing us to create highly specialized sheet metal products. From prototyping to full-scale production, our processes are streamlined to maximize efficiency and precision. Clients across Australia rely on us for bespoke solutions that push the boundaries of traditional metal fabrication.

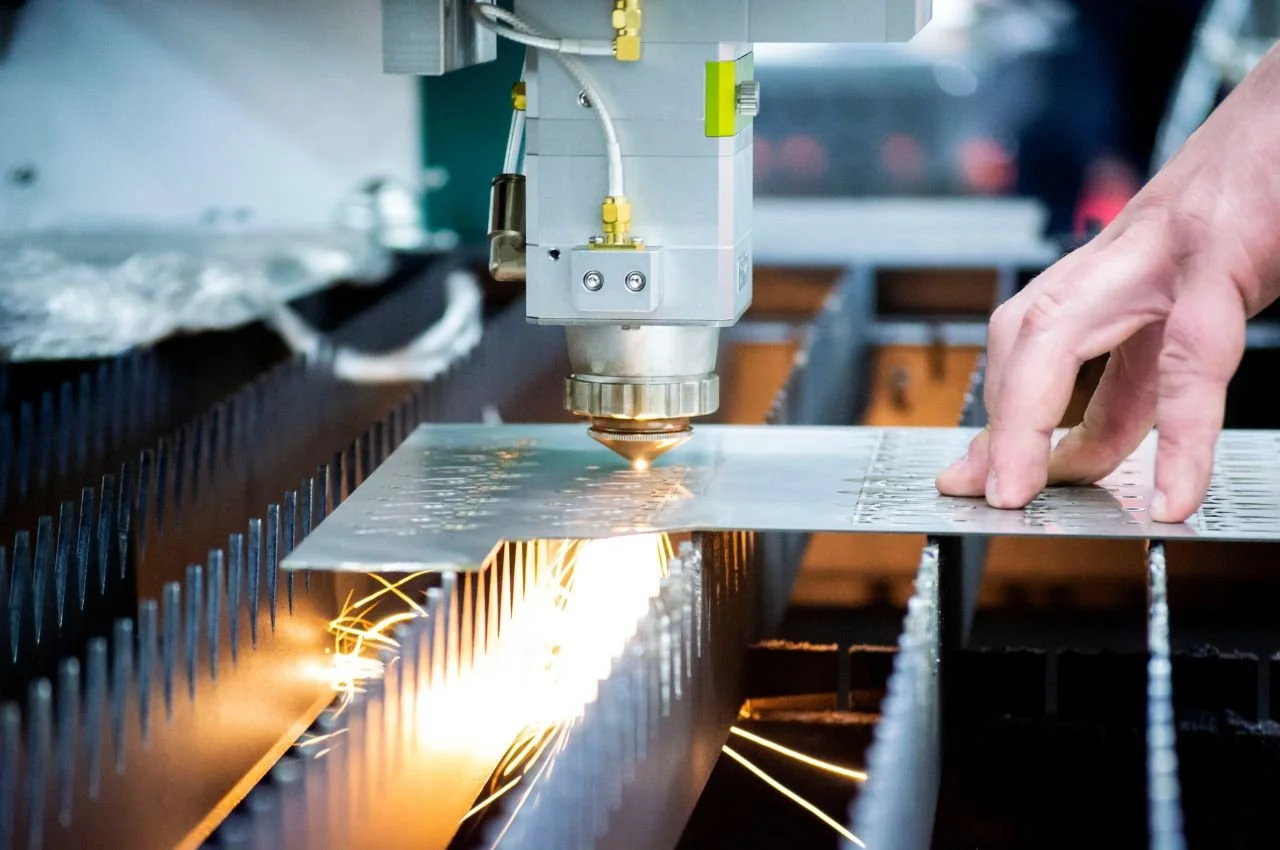

Advanced Sheet Metal Cutting and Bending Techniques

At Ripley Dynamics, our sheet metal cutting and bending services are at the forefront of technology. We employ state-of-the-art machinery that ensures clean, precise cuts and bends, resulting in high-quality sheet metal products. Our skilled technicians are adept at managing complex designs and tight tolerances, making us a leading provider in the metal fabrication industry. Whether it’s intricate components or robust parts, our advanced techniques guarantee that every product meets rigorous standards of excellence.

Expert Sheet Metal Welding and Forming

Sheet metal welding and forming require a high degree of skill, and Ripley Dynamics stands out as a leader in these fields. Our certified welders and formers bring years of experience and a passion for metalwork, ensuring that every joint, seam, and bend is perfect. Using the latest in welding technology, we provide durable and aesthetically pleasing sheet metal products that serve a variety of applications. From industrial machinery to consumer goods, our expertise in metal fabrication services makes us the preferred choice for projects that require superior craftsmanship.

Prototype Development with Sheet Metal Prototyping

Innovation is key to staying competitive, and at Ripley Dynamics, we leverage sheet metal prototyping to bring your ideas to life swiftly and effectively. This service is crucial for testing and refining designs before entering mass production. Our rapid prototyping capabilities allow for fast turnaround times, helping clients visualize their products and make necessary adjustments early in the development process. By integrating cutting-edge techniques in metal parts fabrication, we help reduce costs and time to market, making your ventures more dynamic and successful.

Comprehensive Metal Cutting Services

Ripley Dynamics stands as a beacon of innovation and reliability in the realm of metal cutting services. Our facility, equipped with the latest tools and technology, ensures that every cut is executed with precision and accuracy. We cater to a wide range of industries, including automotive, aerospace, and construction, providing them with tailored solutions that meet their exacting standards. Our metal cutting expertise allows us to handle various materials and thicknesses, offering versatility that is crucial for our clients' diverse needs. The precision of our cutting techniques significantly reduces material waste and increases efficiency, leading to cost-effective production and quicker lead times. With Ripley Dynamics, clients across Australia find not just a service provider, but a strategic partner dedicated to elevating their products with superior metal cutting solutions.

Design and Production of Sheet Metal Enclosures

Ripley Dynamics excels in the design and production of sheet metal enclosures, catering to a multitude of industries that require durable and precisely engineered solutions. Our enclosures are crafted to protect sensitive equipment from environmental hazards and mechanical impacts, making them ideal for electronics, telecommunications, and industrial applications. By utilizing advanced fabrication techniques such as laser cutting, CNC bending, and meticulous welding, we ensure that each enclosure meets the specific requirements and regulations of our clients' projects. Our team collaborates closely with clients to understand their needs, providing customized enclosures that enhance functionality and aesthetic appeal. Ripley Dynamics is committed to delivering products that not only meet but exceed expectations in quality and performance.

Sheet Metal Contractors Delivering Excellence

As leading sheet metal contractors, Ripley Dynamics is dedicated to providing unparalleled craftsmanship and customer service in every project we undertake. Based conveniently in Australia, we serve businesses across the nation, always ready to deliver top-quality metal fabrication solutions right to your doorstep. Our extensive experience and advanced capabilities allow us to take on projects of any scale and complexity, from small custom fittings to large industrial assemblies. Our team of experts works closely with clients to ensure that all specifications are met with the highest standards of precision and efficiency. Choosing Ripley Dynamics means partnering with a contractor who values quality, reliability, and your complete satisfaction. Whether you're in the initial stages of design or need a fast production turnaround, we are the "sheet metal near me" solution you can trust.