Revolutionise Your Production with Plastic Injection Moulding

Redefining Precision: Plastic Injection Moulding Services in Queensland, Australia

Ripley Dynamics stands at the forefront of the plastic injection moulding industry, offering state-of-the-art injection moulding in Sydney, Brisbane and the Gold Coast that caters to a diverse range of client needs. Our expertise in plastic injection moulding stems from a deep understanding of the plastic moulding process, combined with advanced injection moulding techniques. This blend of knowledge and technology positions us as one of the leading injection moulding companies, specializing in custom injection moulding solutions that meet and exceed client expectations.

Our plastic injection moulding services encompass the entire process, from design to production. We work closely with clients to understand their specific requirements, ensuring that every aspect of the project aligns with their objectives. The journey begins with design consultation, where our team of experts collaborates with clients to refine their product concepts. This stage is critical in custom injection moulding, as it sets the foundation for the entire process.

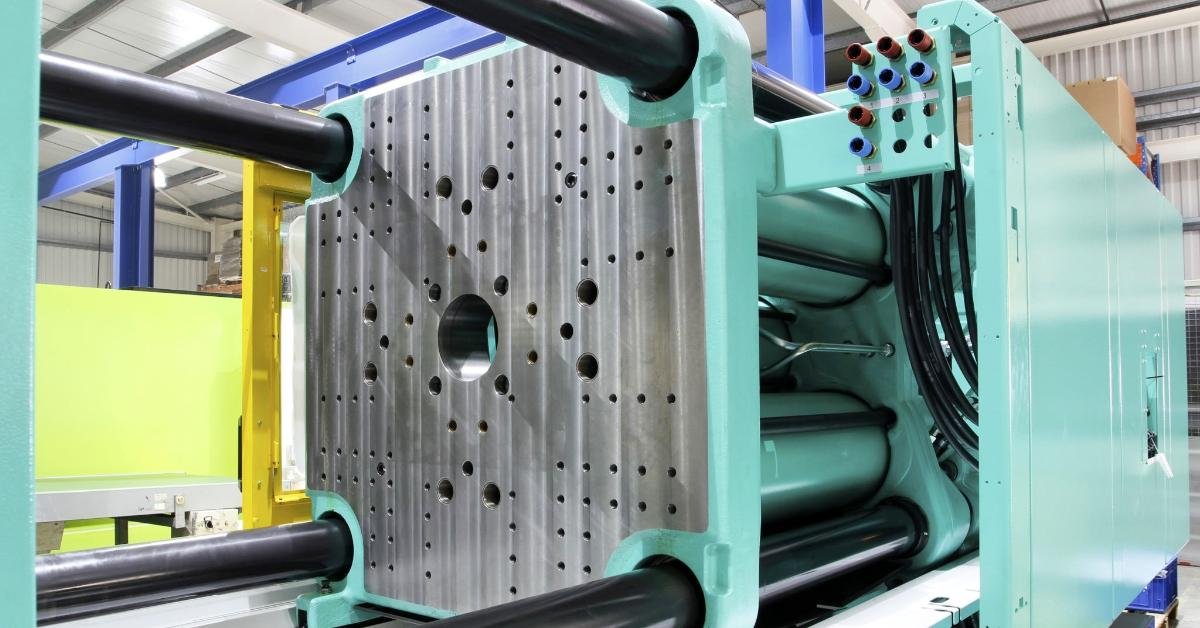

The next step involves the creation of moulds, which are the heart of injection moulding. Our precision plastic moulding techniques ensure that these moulds are crafted with the highest accuracy, reflecting the intricacies of the design. This precision is vital in custom plastic moulding, where even the slightest deviation can impact the functionality and aesthetics of the final product.

Once the moulds are ready, we move to the production phase. Our injection moulding machines, equipped with cutting-edge technology, precisely control every parameter of the moulding process. This level of control is essential for maintaining consistency and quality across all units produced. Our rigorous quality assurance protocols further ensure that each product meets our high standards, as well as those of our clients.

Custom Injection Moulding: Tailored Solutions for Every Need

At Ripley Dynamics, we understand that every project is unique, and our custom injection molding solutions reflect this belief. Our tailored injection molding approach allows us to adapt our services to fit the specific requirements of each client, whether it's a small batch of specialized components or large-scale production runs. This flexibility is a hallmark of our molding company services, setting us apart from other plastic molding firms.

Custom injection molding requires a deep understanding of both the material and the process. Our team of experts selects the most suitable materials for each project, considering factors like strength, flexibility, durability, and aesthetic appeal. This material selection process is crucial in achieving the desired outcome, especially in precision plastic molding where the material's properties directly impact the performance of the final product.

In addition to material selection, our injection molding customization capabilities include a range of finishing options. From textured surfaces to high-gloss finishes, we can achieve the exact look and feel that our clients desire. This attention to detail is what makes our personalized molding solutions stand out.

Our commitment to customization extends to our support services as well. We offer comprehensive assistance throughout the project lifecycle, from initial consultation to post-production support. Our goal is to ensure that every aspect of our injection molding services aligns with the client's vision, providing a seamless and satisfying experience.

Understanding Plastic Injection Molding Cost with Ripley Dynamics

Businesses seeking to make informed decisions about their manufacturing processes need to understand the complexities of plastic injection molding cost. At Ripley Dynamics, we recognize that cost is a significant factor for our clients, and we strive to provide transparent and comprehensive insights into how these costs are structured. The cost of plastic injection molding is influenced by various factors, including the complexity of the design, the type of material used, the quantity of parts produced, and the level of customization required. For instance, intricate designs that require specialized molds or unique materials may increase the overall cost. Similarly, the economies of scale play a significant role – higher quantities often reduce the cost per unit, making large production runs more cost-effective.

Our team works closely with clients to identify cost-saving opportunities without compromising on quality. This could involve optimizing the design for more efficient production, selecting cost-effective materials that meet the project's requirements, or advising on the most economical production volumes. Additionally, Ripley Dynamics invests in advanced technology and efficient processes to minimize waste and reduce production time, further optimizing costs.

Innovative Techniques in Injection Molding: A Cornerstone of Ripley Dynamics

Innovation is at the core of Ripley Dynamics' injection molding services. Our injection molding techniques are continually refined to incorporate the latest advancements in the field. This commitment to innovation allows us to offer cutting-edge solutions that address the evolving needs of the injection molding industry.

One area where our innovation shines is in the efficiency of our injection molding production. By optimizing our processes, we can achieve faster turnaround times without sacrificing quality. This efficiency is particularly beneficial for clients looking into injection molding outsourcing, as it ensures that their projects are completed within the desired timeframe.

The injection molding technology allows us to handle complex designs with ease. Our advanced machines are capable of producing intricate shapes and fine details, making them ideal for projects that require a high level of precision. This capability is a significant advantage in the competitive world of injection molding manufacturers.

In addition to our technological prowess, our expertise in the injection molding process itself sets us apart. Our team has extensive experience in various molding techniques, enabling us to tackle challenges that others might find daunting. Whether it's dealing with difficult-to-mold materials or achieving tight tolerances, we have the skills and knowledge to deliver exceptional results.

Ripley Dynamics' injection molding services are defined by our commitment to precision, customization, and innovation. Our expertise in plastic injection molding, combined with our state-of-the-art facilities and dedication to client satisfaction, makes us a preferred partner for businesses seeking top-quality injection molding solutions. Whether you're looking for a reliable injection molding supplier or need assistance with a complex project, Ripley Dynamics is here to help.